TECHNICAL RUBBER PRODUCTS

The applications of compact rubber products are many in every sector and embrace all the technologies available within the SOGO group.

We realize our components through injection molding, with thermo-assisted injection, compression or transfert, processing compounds in natural or synthetic rubber (SBR, EPDM, CR, IIR, NBR, VMQ, FKM, FPM, HNBR, AEM, ACM); in SOGO compounds production, there are EPDM based formulations with high resistance to high temperatures up to 900 °.

The components are widely used for the first plant in the automotive sector, ranging from the engine compartment to the chassis, from the car to the body.

Impressive use of compact rubber vibration dampers in tramway armaments. Wide possible applications also in industrial sectors.

The applications of the foam rubber products are specific for the automotive, civil and construction sectors, and involve the entire press fleet with compression technology of the SOGO group.

We manufacture our components through compression or transfert molding, processing synthetic rubber compounds based on EPDM.

The components, mostly gaskets and soundproofing, are used for the first plant in the automotive sector in interior or body applications.

The applications of rubber products with metal and / or plastic reinforcements are many for the automotive sector and for the civil sector.

We realize our components through injection molding, with thermo-assisted injection, compression or transfert, processing compounds in natural or synthetic rubber (SBR, EPDM, CR, IIR, NBR, VMQ, FKM, FPM, HNBR, AEM, ACM); in SOGO compounds production, there are EPDM based formulations with high resistance to high temperatures up to 900°.

Based on the requirements of the various reference specifications, the reinforcements are designed and selected among the best reclaimed steels on the market, or among the best thermoplastic materials with high mechanical characteristics such as Nylon loaded with glass fiber, charged acetates and highly resistant to high temperatures and cold.

Applications by way of example: automotive, industrial, iron-metro-tram and civil / anti-seismic

The applications of the silicone products (VMQ) are used on special components for the automotive, electrical and chemical sectors, and involve the entire press fleet with injection and compression technology of the SOGO group for silicones in paste, in order to obtain components with high precision, no burr and with automatic processes.

The particularity of this elastomer (VMQ) is that of resisting high temperatures, which is why many components such as anti-vibration, gaskets, cable glands are used inside the engine compartment or near the exhaust system.

FLUOROSILICONE MOULDING

The applications of the fluorosilicone products (VMQ) are used on special components for the automotive, electrical and chemical sectors, and involve the entire press fleet with injection and compression technology of the SOGO group for silicones in paste, in order to obtain components with high precision, no burr and with automatic processes.

The fluorosilicone (FVMQ) is an elastomer with characteristics superior to the traditional silicone, as in the mixture there is a fluorine content (in% polymer) which gives the elastomer excellent chemical-physical properties, good mechanical properties, high resistance to fuels and ozone.

COMPONENTS ASSEMBLY ON CUSTOMER REQUESTS

Many technical items are completed through the assembly of different components for each polymer matrix.

Through complete lines of positioning and control templates, SOGO is able to guarantee to the customer complex components equipped with accessories and micro accessories perfectly positioned and oriented in the positions provided by the reference mathematical models.

RUBBER COMPOUNDS DESIGN AND PRODUCTION

SOGO specializes in the design and production of rubber compounds for the most varied applications and industrial sectors.

The know-how acquired in over 50 years of experience makes the compounds the point of origin of the industrial process for the realization of the finished product.

SOGO specializes in the formulation and production of compounds based on the following polymers: SBR, EPDM, CR, IIR, NBR, HNBR, AEM, ACM, BR, which are processed with ingredients such as active fillers, protective agents, vulcanizing agents and plasticizers.

With these formulations SOGO is able to produce black compounds and coloured compounds, used for injection molding, compression, transfer, extrusion, calendering.

MIXES ON OUR CUSTOMIZED FORMULATIONS

Responding to the multiple needs of the market and the range of possibilities that can be obtained by mixing polymers and other components, the Mescole Division now boasts a recipe book of over 1,000 formulations, which represent an immense technological heritage capable of enhancing customer expectations

- Consultancy aimed at solving customer design issues in the pre-series phase

- Engineering support for defining design features and drafting the supply specifications

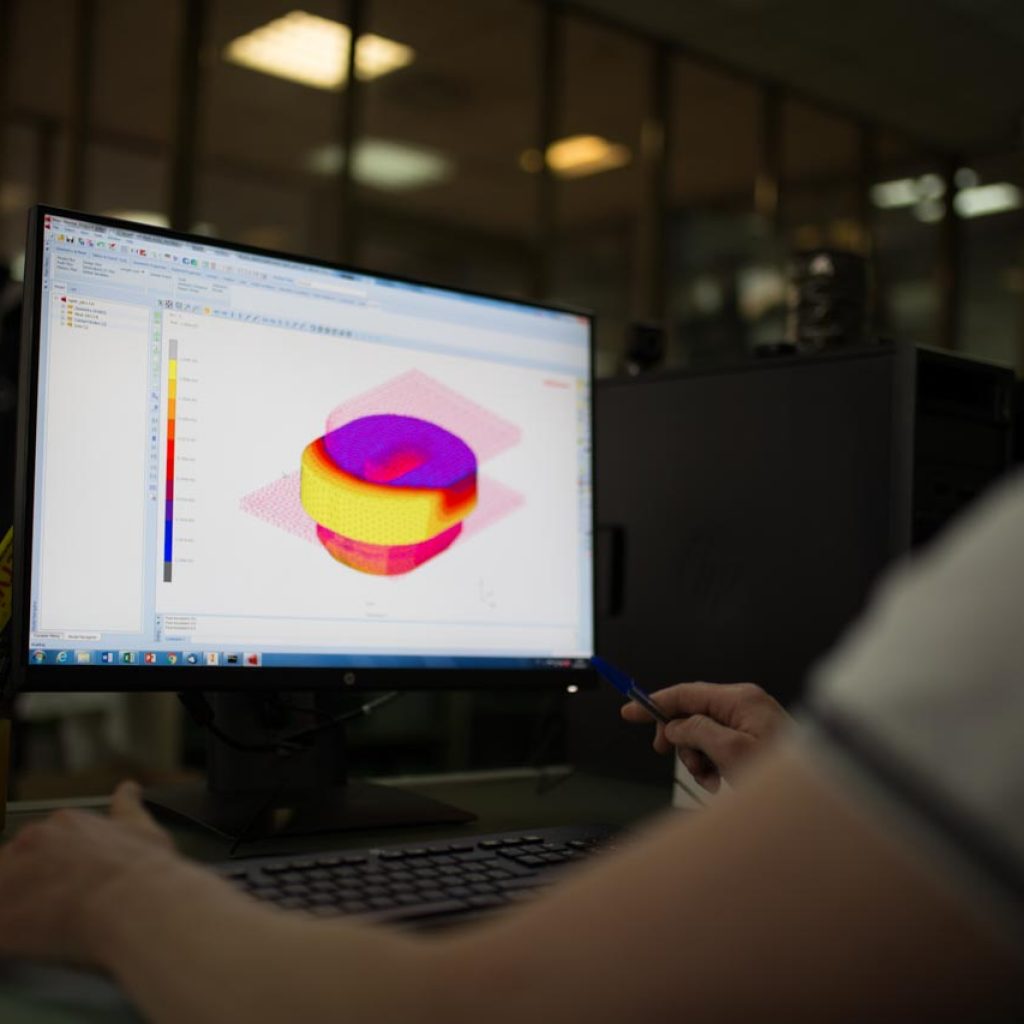

- Simulation analysis for the behavior of elastomers – Finite Element Analysis (FEM)

- Prediction Life

- Characterization of rubber compounds

- Characterization of components

- Fatigue tests

- Industrialization and installation of the production process

RAPID EXECUTION IN 24/48 HOURS OF SAMPLES

SOGO specializes in the production of samples for rapid prototyping using silicone molds that can print rubber-like materials, like polyurethane and plastic with excellent surface quality and reproduction of details with functional characteristics similar to the finished product.

SOGO is able to realize prototypes with other printing technologies:

– selective laser sintering (SLS) with polyamide based materials

– stereolithography (SLA) with stratification of solidified liquid resins.

REALIZATION OF SAMPLES THROUGH THE USE OF LOW VOLUME MOLDS

Through its consolidated experience in the design and industrialization of molding equipment, SOGO specializes in the production of prototype samples from low volume molds in just a few days.

The low-volume molds accurately replicate the same characteristics of the standard molds, in terms of geometric characteristics and technical characteristics of the component, with the possibility of also producing thousands of pieces that can be used to meet the multiple needs of customers (tests of mountability , bench tests, mechanical characteristics and others).

Low volume equipment can be modified upon customer’s request for any development iterations.

he materials used for molding the samples are the same as those used for molding the series components.